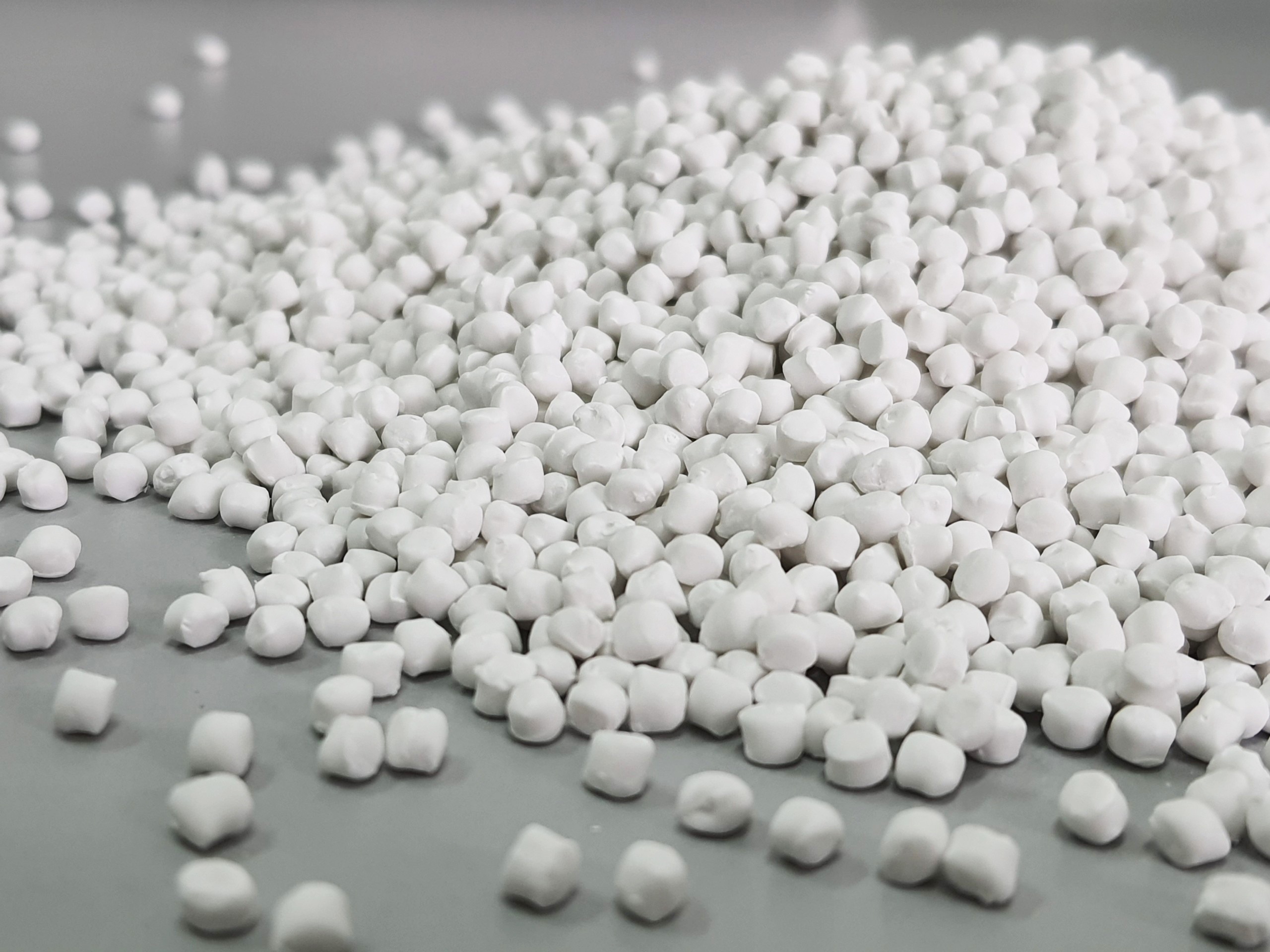

The filler masterbatch is designed to break down naturally through microbial action, reducing long-term pollution and waste. In industrial composting facilities, the material can decompose into non-toxic components within a short period, turning into compost that enriches the soil.

Using plant-based or other renewable materials for the filler masterbatch reduces dependence on fossil fuels and decreases carbon footprint. Sourcing agricultural by-products or waste for the filler ensures that the production process supports sustainable farming practices.